WDG pesticide production line

Description:WDG water dispersible granule pesticide process and equipment flow: raw material ----- mixing (dry material) --- airflow crusher --- kneading (wet material) --- granulation --- drying --- sieving --- unqualified (large particles) --- crushing (swing granulator) --- granulation again if: unqualified (small particles) ----- granulation again; Qualified -------- Packaging!

Details

WDG pesticide production line

Description:WDG water dispersible granule pesticide process and equipment flow: raw material ----- mixing (dry material) --- airflow crusher --- kneading (wet material) --- granulation --- drying --- sieving --- unqualified (large particles) --- crushing (swing granulator) --- granulation again if: unqualified (small particles) ----- granulation again; Qualified -------- Packaging!

Details

Background and significance of equipment: Food is one of the four prominent issues worldwide. According to the statistics released at the end of June of the World Population Conference, it is estimated that the world population will reach 9 billion to 10 billion by the middle of this century. China is a country with a large population. To feed nearly one fifth of the world's population, farmers must have a good harvest. In order to ensure a good harvest in agriculture and the interests of farmers, the Chinese government and relevant research institutions have made great contributions. It is well known that farmers can't get a good harvest without pesticides, which can be divided into powder, wettable powder, emulsifiable oil, suspending agent and granules.

Granule (GR) is referred to as granule, which is a granular preparation processed from raw drug, carrier and other auxiliary agents. The early field test of granule was started in 1946. In the early 1950s, it was widely used in the United States. In the early 1960s, it was widely used in Japan. In the late 1960s, due to the development of environmental protection science, in order to avoid the pollution of the environment and crops caused by the particle drift when the pesticide powder was spread, the pesticide particles were widely used all over the world. The development of granules in China was mainly in the late 1970s. According to the statistics of the Ministry of Chemical Industry in 1989, granules accounted for about 7% of the total pesticide preparations.

The reason why granule can become a common pesticide is that it has many incomparable characteristics. The characteristics of granule are:

① The direction of pesticide application can ensure that the pesticide can reach the target organism sufficiently and be beneficial to the biological safety of natural enemies;

② The drug particles do not attach to the stems and leaves of the plant, so as to avoid direct contact with the drug damage;

③ There is no dust flying and no pollution to the environment during the application;

④ During the application process, it can reduce the amount of drugs attached to or inhaled by the operator to avoid poisoning accidents;

⑤ Reduce the toxicity of highly toxic pesticides to avoid human and livestock poisoning;

⑥ It can control the release rate of the active ingredients in the granules and extend the shelf life;

⑦ Easy to use and high efficiency.

Some of the incomparable characteristics of granules make it a better agent.

Applicable materials:

WDG water dispersible granule products: 25% thiacloprid, 50% enoylmorpholine, 10% phenyl ether, 80% flufenitrile, 70% thiophanazole, 48% azolamide, 70% imidacloprid, 70% acetamiprid, 80% thiobiscarb, 80% butyl urea, 70% benzsulfuron, 80% dipyruron, 70% azithron, 60% methasulfuron, 25% (75%) chlorsulfuron, 60% bensulfuron, 80% aluminum phosphide, 50% diniconazole, 10% difenoconazole, atrazine, 75% benzsulfuron, 75% chlorsulfuron 40% velochlor, 90% chlorothalonil, 80% regent, 50% phenoxystrobin, 3% regent, 80% sulfuroxim, avermectin, 50% azoxim, 10% difenoconazole, 40% oximazone, 75% tricyclazole granules, nicosulfuron, 25% sulfsulfsulfuron, 75% trifluoriduron, 25,50% azoxystrobin, 10% cyclazol, 75% isooxazolone, 50% pirimid, 50% oxime, 15% ethoxysulfuron, 75% chlorpyrisulfuron, 75% carbendazim 60% anklefenozide, 10% flusilazole, 64% mancozeb+8% metalaxyl, 18.7% enoyl pyrazolate, 75% chlorsulfuron, 57.6% copper hydroxide (crown colony), 52.5% oxoxazofenozide (Yikuaijing), 20% fipronil

Process flow and production equipment:

Process 1: weighing and batching → soft material preparation (trough mixer) → granulation (YK-160 swing granulator) → drying (CT-C series hot air circulation oven is selected according to the output) → screening (ZS oscillating screen is selected according to the output) → packaging

Process 2: weighing and batching → mixing (high-efficiency wet mixing granulator) → wet granulation (YK-160 swing granulator) → drying (boiling dryer selects model according to output) → screening (ZS-1000 oscillating screen) → packaging

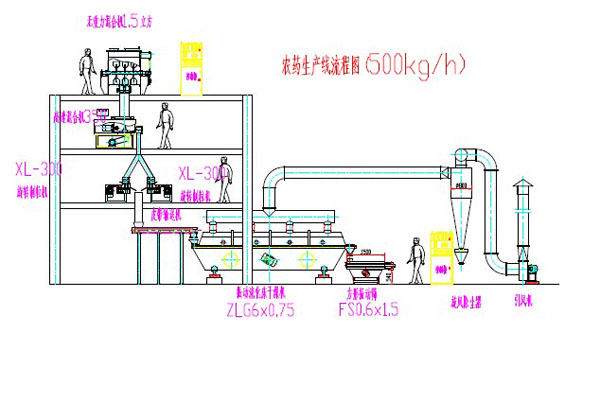

Process 3: weighing and batching → dry mixing → fine pulverizer → dry mixing → wet material mixing (vertical high-speed mixer) → granulation (XL-300 spinning granulator) → shot blasting (can be selected according to the process needs) → drying (FG-type fluidized bed dryer, vibrating fluidized bed dryer according to the output) → particle vibrating fluidized bed dryer → screening (square vibrating screen according to the output) → packaging

Process 4: weighing and batching → soft material preparation (trough mixer) → granulation (twin screw extrusion granulator) → drying (fluidized bed dryer or vibrating fluidized bed dryer according to the output) → screening (ZS vibrating screen) → packaging

Process 5 Weighing ingredients → mixing → dry granulator → sieving → packaging instructions: the above processes are in sequence, the lower down, the greater the particle density.

Suggested process: WDG water dispersible granule pesticide process and equipment flow: raw material ----- mixing (dry material) -- airflow crusher -- kneading (wet material) -- granulation -- drying -- screening -- unqualified (large particles) -- crushing (swing granulator) -- granulation again If: unqualified (small particles) -- granulation again; Qualified -------- Packaging!

Previous Information:None!

Next Information:None!

优质案例

PROJECT